Trucking Onwards With Big Wrenches (Part 2)

Well Hello There Hivers And Technicians

The end of the year is drawing closer and closer, usually one would be excited at that and I am no doubt. But we still have so much work to finish up before we can go squeeze our toes in the sea sand and relax. What can I say the more we finish the more we want to finish.

Okay lets forget about the sandy beaches for a moment, the holidays are still some ways off!

In the last post I made in the #hivemotors community was one where we had to do some major servicing work on a Tata truck. In that post I shared how and what I did regarding the fly-wheel and clutch assembly to get it ready for the transmission fitment. Along with that we had some other simple stuff to swap out here and there. Basically just gave it a lot more love than it actually needed. Always a good thing though, prevention is better than cure.

Incase you missed the previous post, give it a quick scroll through. Trucking Onwards With Big Wrenches

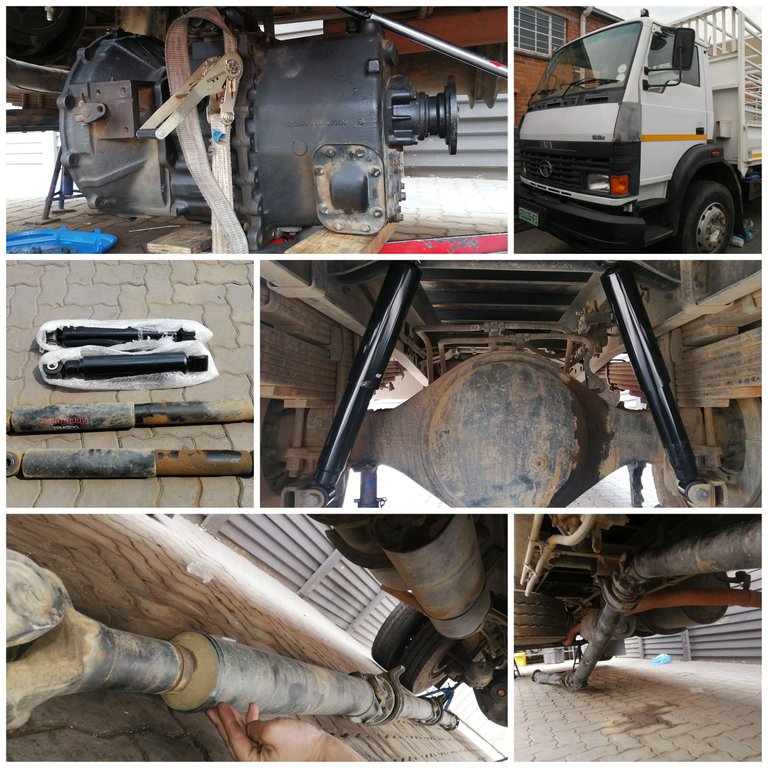

Strapping Down That Transmission

So the weather was nice, it was cloudy and as I mentioned in the previous post that's proper weather for a technician, well it most certainly is for me!

Hard work and no sweat!

Getting this transmission on the jack itself proved to be quite some work. It could have been so much less hassle if we just decided to hoist the truck a little bit higher. But no we are all a bunch of productive lazy asses! Laughs Laughs well the transmission was already under the truck and we had to sort of pull it over and onto the jack sideways because there was too little room for it to go on upright, we then had to turn the transmission over onto it's belly so that it can stand upright.

It was a mission! Getting the jack and lifting the truck would probably have been easier. 🤣

Strapping that Big Betty in with a cargo strap seemed like the wisest idea. I certainly didn't want to leave work with half a face left it that bugger came tumbling down!

See, I ain't really getting old. Screw all those kids that are starting to call me uncle! Screw all of them. I think I'm still doing pretty great! She's lined up nicely and the splines took! Okay she's a bit closer at the bottom than at the top but it has a little play and it's well within the boundaries. All I can do now is pull her in gently with the bolts.

The Gear Linkings

Well I always believe that it's better to forget the oil than to forget the gearlink on a transmission. Laughs no I'm joking ofcourse! However can you imagine forgetting the link and then starting the truck while it's in gear and you didn't press the clutch because you thought oh the gear lever feels like it's in neutral.

Hah shit happens real fast!

Well this is a simple gearlink to say the least. It has splines but it also has a key way in which the bolt slips through so getting the spline placing right on the link isn't that hard of a task as I first thought!

Now For The Hardest Job Of Them All.

Well it's actually very easy! Very very easy. The trick over here is that the prop-shaft for this Tata truck is almost three times my length, almost. It's definitely more than twice.

Besides the length, it really is a pretty heavy piece of metal even though the pipes are hollow. I couldn't believe it myself!

What did I do?

"Yeah, what did you do?"

Well I kept my pride and didn't call for anyone to come help me! No, oh no I'm a big boy!

How stupid of me ey? I'd rather struggle onward then call for help. See the trick was holding it in place and using hands to screw in the bolt and nut for it to sort of hang in the air on it's position.

I started at the rear where the differential is located and worked my way to the front. I don't exactly know why I started at the rear but it did seem to be the better option at that time, I dunno?

I then starting bolting down each mounting one at a time by holding it up with my feet!

Yeah, can you imagine me lying on my back bench pressing the prop-shaft with me legs struggling to get the bolts in.

Imagine this, what if that pipe decided it doesn't want to be in the air anymore? Would I be no teeth Billy? Or blind ass Willy?

She's right where she needs to be! Right frikkin there! It was a colossal struggle but atleast I left my pride fully intact and unscathed!!

How about that!

Most technicians tend to ignore this, but I prefer bending the plates over for a little bit of extra fastening security and well a little piece of mind that it won't come loose and end up being blamed for something so stupid.

Be Done With The Heavy Work!

Okay so the heavy work is behind me! I got some shocks to replace and a few lug nuts and studs on one of the rear wheels! Fairly easy and quick, however the sun started coming out and I bathed in the glorious heat of though sunrays! Now that's where the job started turning into a frustration at the easiest part!

Comparing new parts to the old parts.

That is something I am very fond of.

No the shocks aren't shorter, they are merely squeezed in. The nice fresh black paint looks, well it looks drooling, to say the least. 🤣🙃

If I'm honest I would have settled for a water pressure wash but I can't always have my way! It would have certainly made the shocks and the whole vibe look so much better.

But the Bossman is probably right we are no vale car wash service! I can agree with that!

The Big Airtool And The Lugs

Well I am at the final stretch of work on this truck. Spun out a few lug nuts and refitted the new ones, it wasn't actually needed to replace the studs on the wheels I am somewhat unsure why the big boss ordered them. Thinking about it perhaps you bought both of them together? It's the only logical explanation!

Notice in the top right corner is a new blackened nut, those are on of the new nuts. I think it only missed a few nuts. nothing that poses too much of a concern. Aslong as 80% of them are still there I'm sure nothing will happen. I mean the worst that can happen is the wheel comes off, no biggy? 🤡

She's clutching great and purring like the kitten she is!

Connecting the people of #HIVE across South Africa. #hive

Definitely this truck has fought good battles and has given a lot of if, because there is much to do, the box, the cardan, the suspension and stop counting, I see that you have taken time to go solving everything, I guess as you bring you the parts, I hope soon share with us photos of the final result.

Yeah and we've left some stuff out hey, didn't do EVERYTHING.. But sometimes I feel doing more is better.. I dunno some people would disagree but that's okay😉

I did a major service on my vehicle about a week ago, I replaced so many rubbers and seals that wasn't really necessary but I did it none the less. I have to drive some distance December so gotta make sure it gets to where I need to be👍😎

It seems to me that if you have the availability, and I mean the money, make those extra changes aren't too much, it's a healthy practice for the vehicle.

It is true that the work done has been very hard, usually in the mechanical work there are many obstacles such as little space and others.

I hope no studs come out and thus the wheel 😁. Thanks for sharing the truck post I hope you culminate soon because you say it's in the home stretch. Regards

I certainly do hope so as well, you know the wheel staying on 😂..

Thanks a lot for the comment!

Yeah space is sometimes a big issue😂 and can lead to a lot of frustration! But sitting back taking a deep breathe can help a lot at times😂😂

You really don't know how I understand that, I've had to help my husband and previously my father in fixing his vehicles and sometimes it's hard to be flexible 🤭.

Thanks to you for responding to my comment. I look forward to continuing to see your posts. In my case I will soon post in this nice community. Greetings and success 👋👋

https://twitter.com/1205092265615659008/status/1603593462963748864

The rewards earned on this comment will go directly to the people( @technicalside ) sharing the post on Twitter as long as they are registered with @poshtoken. Sign up at https://hiveposh.com.

The shocks look so nice, nice job on installing them.

Gotta say they do have some satisfaction to look at 😎👀😂

Agreed (^_^)

Hey Bro, thanks for sharing your work here, I look forward to seeing the final result, wow! It's quite a lot to do there, but I know it will be worth it.

The best part of it all is seeing your workpiece driving away all neat and fixed😎 a sense of pride I suppose😜

Thanks a lot, im really glad this community exists 😂 otherwise id have to post in planetauto and that doesn't quite fit what I share😂😂😎😎

Yes, it is very satisfying. You look at all your work with pride and well about the other LOl haha, we're glad to have you here.

For us at #hivemotors it is always a pleasure to have your content, we are glad that you are the kind of technician who goes beyond what you should do, that speaks of you as a good professional.

Im very happy about that😊

Although I will be taking some time off from the workplace for a week or three.. But perhaps I'll squeeze in a post or two still. I have a lot of content that I still need to share😝 So much that I actually cant take a break!

I feel honored thanks 😊 I've been a little bit on the shy side with giving support the last few weeks... So this holiday ill be jumping back in

It's a very good job, please don't take it the wrong way. But from mechanic to mechanic. Ask for help with the heavy parts, your health comes first, and I've already seen young mechanics get injured for life with a wrong move.

Which is a real shame.

I hesitated to make the comment, I do not want you to take it the wrong way.

No I do get what you're saying 😅 I do.

And I should rather get help then try and do everything myself. And more so if I have the help I need right there in the shop 👉

Thanks for the comment though

No, that's the nice thing about Hive, freedom of speech. You should say what you will...

My left arm was ruined, and the pain often doesn't let me do anything.

That's why I try to warn you, thanks for not taking it badly.