Day 30-32 of the Debmar Atlantic 2024 Project - Wrapping things up before Drydock

It is the last few days of wrapping up on site. I got behind on this journal so I have thrown the last 3 days into one post.

As usual, this location gives some spectacular view while simultaneously having a site that is physically gruelling. It is not just about the distances one has to travel and the stairs one has to climb, it has to do with the fact that these are hot days and by necessity you wear a full overall with full PPE gear.

Its time to pack up and get rid of all the waste inside the container!

Right now the container looks a bit like a mess but this is us sorting things out. There are tools going back to the workshop and stock that we will be using only during the commissioning phase - like Refrigerant, oil, dryer cores etc.

There are also spare air filters.

I worked late this evening as I needed to complete Technical Reports.

This is a 24 hour site with some companies running a night shift crew from 7pm till 7am as well.

The ever-awake Zak. I am not a nightowl or an early bird. I am just awake all the time... I sleep very little... I am at my limits.

The "permanently exhausted pidgeon".

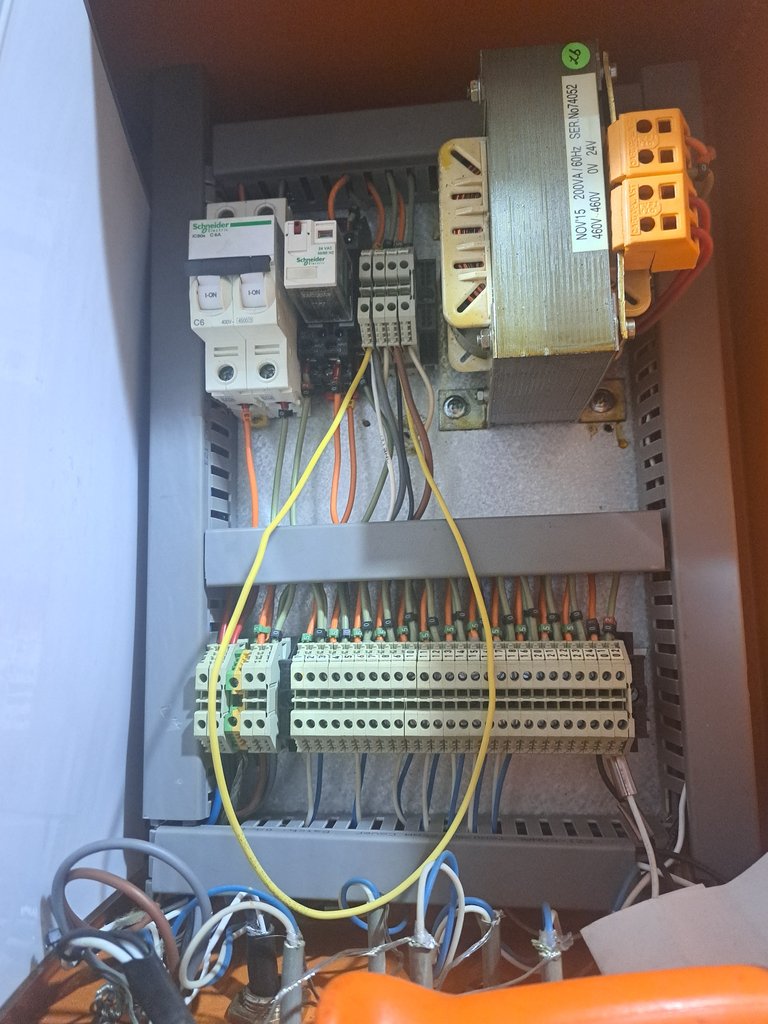

Some of the switchboard that give our units power.

A sorted out and neat container.

My boss and I came to site to start the units, there was an Fire E/Stop in effect from the Bridge. So we needed to bridge that wire out and force the units to run.

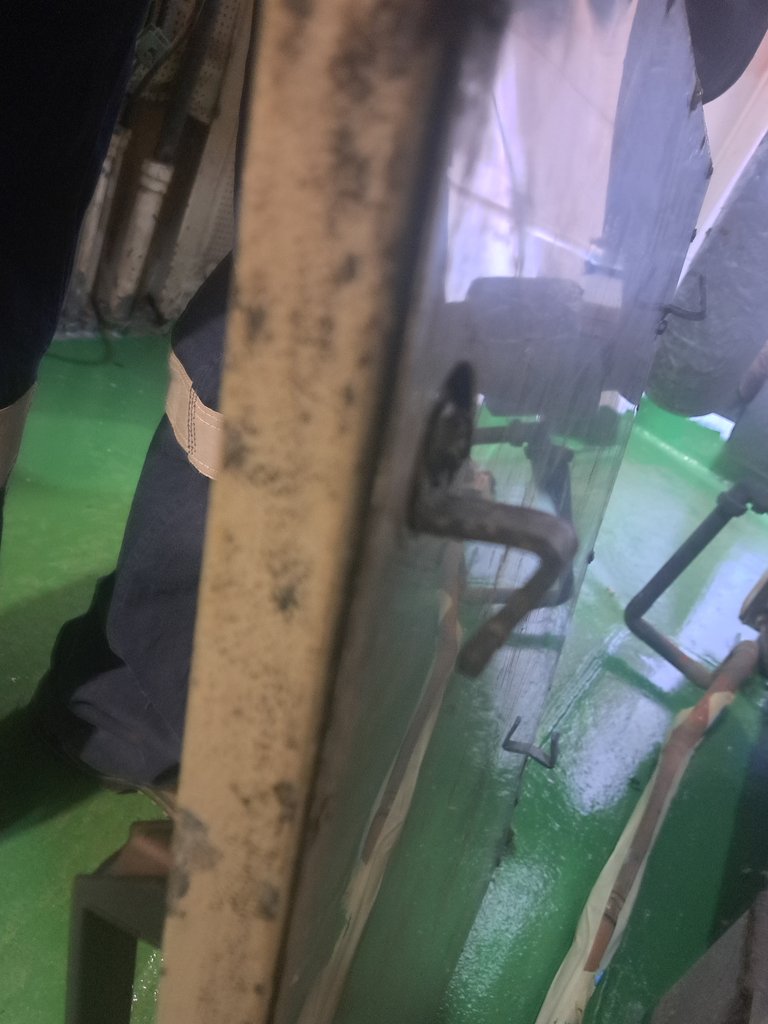

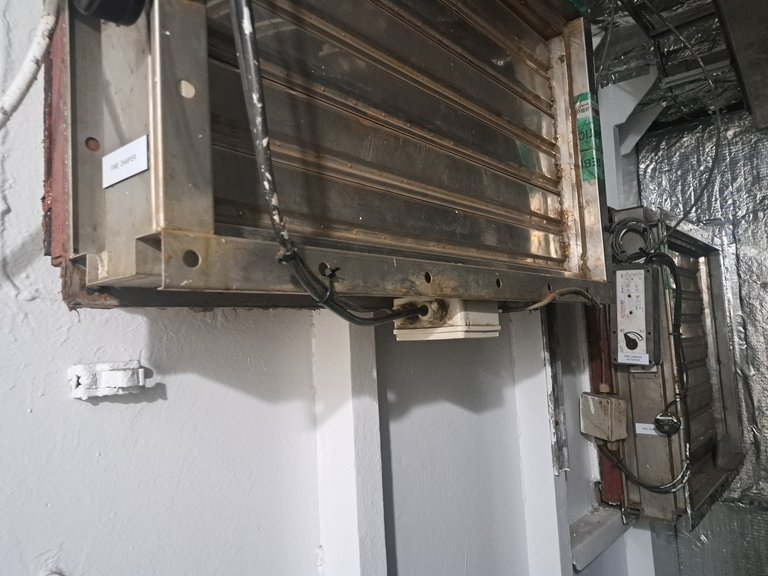

There was an issue with some of the doors, leaking a lot of air. Someone had replaced the original door cams with these squiggly things. Not very good.

This is the door cam. It has a teardrop shape so it tapers in as you close it.

At this point I am on my own, sorting out the snags on my own.

On one hand, we were told to leave site and come back for commissioning. Then called us back like a day later. Now I am on my own because the company has allocated staff to various sites and they are all busy.

More neatening up by me.

I then installed new camlocks. The two at the top I had to cut into the door with a hole-saw and put them into that location because the original door cams are above that white beam which means that I cannot lock them due to the obstacle.

There were some air leaks on the back of the AHU as well which I sealed up with a silicone sealer.

Even with the new door cams, there are still air leaks. I have applied a semi-temporary door seal to the outside of the door because these doors do not need to open and close all the time as the door has no v-belts.

There is therefore nothing that needs to be maintained all the time on the AHU. If they need to open up the AHU every 12 months it would be a lot.

And that is it for now... I still have so much work to do...

Thank you for reading this post!

Cheers!

@zakludick

Pushed to the limit on hot days, perhaps working at night more suitable. Neat storage and fix-up, hope you taking a good long break in December to switch off not worrying about leaks or disarray!

!BEER

I hope I get the leave time that I have booked. There is a chance that DBM call me back during the first week of my leave. This would cancel my leave.

Hope not, everyone need a good break, unfortunately all too often many not getting that time leading to health issues later in life.

Indeed... I am heading for all of that...

View or trade

BEER.Hey @zakludick, here is a little bit of

BEERfrom @joanstewart for you. Enjoy it!If you like BEER and want to support us please consider voting @louis.witness on HIVE and on HIVE Engine.