Forklift diagnosis and repair

Greetings,

Dear friends once again here, this time I had to make a diagnosis to a Toyota 4g25 forklift or elevator, this equipment is somewhat old but in Venezuela many companies still keep them active.

The equipment according to those in charge of the company told us that they had recently made a general reconstruction, but once the equipment started running and warmed up, it neutralized the transmission and generated a lot of difficulty to lift the loads.

This work was received by a friend who is just getting into doing work on heavy equipment with companies and decided to contact me to make the diagnosis.

Upon arrival and test the first thing I tell him is that there is a problem of clogged oil filter, the second thing he observed is a very strange noise in the torque converter, we chose to evaluate the oil path by disconnecting the cooling system which we found it clogged.

The consequence that generated this obstruction was the forced work of the torque converter since the oil did not make its usual route, the oil did not circulate as it should leaving some parts of the transmission working without oil.

We disassembled the transmission and replaced the torque converter, which had to be taken to a specialized workshop for its reconstruction, since the new spare part is not easy to find because it is so old.

We took advantage of removing the engine and transmission to do a general cleaning and painting of the parts, these activities should have been covered in the rebuild but there was no evidence of any of that.

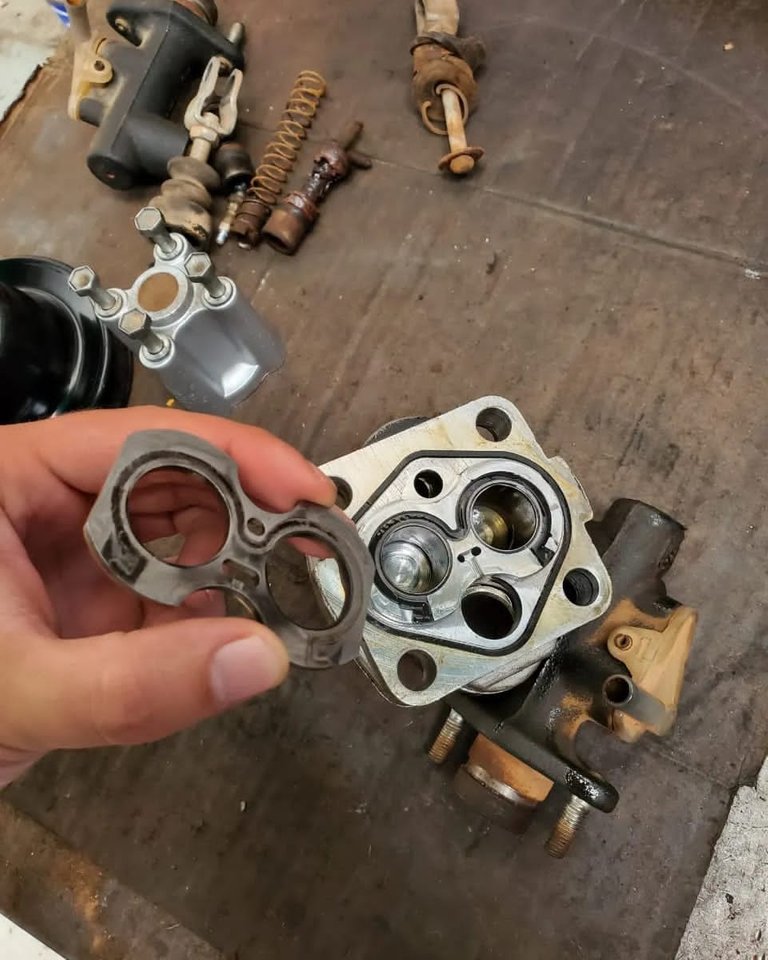

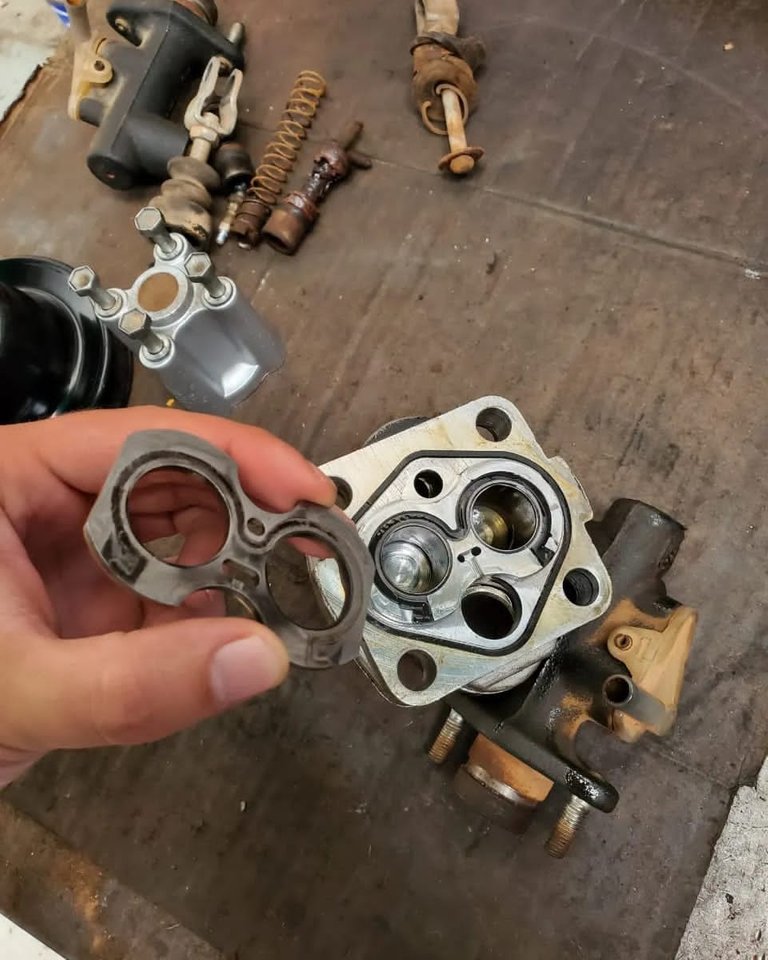

The next thing that was done was to replace the internal parts of the hydraulic system pump which had wear and tear and that generated the difficulty to lift the load.

Also took advantage of correcting leaks in the engine by replacing the crankshaft and cam stoppers as well as the valve cover gasket, also washed and painted before installing.

Once we installed everything again we took the opportunity to replace all the hoses of the hydraulic system so that the equipment can have a zero hour preventive maintenance from everything already done and be able to operate uninterruptedly.

When we started up the equipment it operated correctly so we sent it to the company for delivery, when the equipment was already in operation we received a call that the failure in the load elevation persists so we went there to verify what was happening.

Upon arrival we noticed that the equipment was being operated incorrectly in many ways, the first we noticed is that the operators were using the transmission brake as a croche which overheated the transmission and when it was time to lift they were lifting a load of 2000kg.

It was necessary to explain to them that this equipment is designed to work with a nominal load of 2000kg and due to the time that the equipment has been in use they should not exceed 1500 to 1700kg as maximum capacity, there if the equipment worked perfectly so we are organizing to provide training to the operators of the company to avoid unnecessary damage and the possibility of work accidents due to bad operations.

Once these equipments are used improperly, the risks of accidents increase a lot because the center of gravity of the equipment varies and it can turn over or be suspended in the rear part, without taking into account that it can damage the internal part of the hydraulic cylinders, which can cause the load to collapse.

All these possible failures bring many risks and unnecessary expenses for the company.

I hope you liked this intervention, thank you for reading my lines and may God bless you greatly.

The photos are my own taken with the Infinix Hot 10 i cell phone.

SPANISH

Saludos,

Queridos amigos una vez más por aquí, en esta oportunidad me tocó hacer un diagnóstico a un montacargas o elevador Toyota 4g25, este equipo es algo viejo pero en Venezuela aún muchas empresas los mantienen activos.

El equipo según los encargados de la empresa nos hablaron que recientemente le habían realizado una reconstrucción general, pero el equipo una vez iniciaba marcha y calentaba se neutraliza a la transmisión y generaba mucha dificultad para elevar las cargas.

Este trabajo lo recibio un amigo que apenas se está adentrando a realizar trabajos a equipos pesados con empresas y decide contactarme para hacer el diagnóstico.

Al llegar y probar lo primero que le digo es que hay un problema de filtro de aceite tapado, lo segundo que observó es un ruido muy extraño en el convertidor de torque, optamos por evaluar el recorrido del aceite desconectando el sistema de refrigeración el cual lo encontramos tapado.

La consecuencia que generó está obstrucción fue el trabajo forzado del convertidor de torque ya que el aceite no hacía su recorrido habitual el aceite no circulaba cómo debe dejando algunas partes de la transmisión trabajando sin aceite.

Desmontamos la transmisión hicimos reemplazo del convertidor de torque el cual tocó llevarlo a un taller especializado en su reconstrucción ya que por ser tan viejo el repuesto nuevo no se consigue con facilidad.

Aprovechamos que retiramos el motor y la transmisión para hacer una limpieza general y pintar las partes, estás actividades debieron ser cubiertas en la reconstrucción pero no había evidencia de nada de eso.

Lo siguiente que se hizo fue reemplazar las partes internas de la bomba del sistema hidráulico las cuales tenían desgaste y eso generaba la dificultad de elevar la carga.

También se aprovechó de corregir fugas en el motor reemplazando las estoperas del cigüeñal y la leva así como la empacadura del tapa válvulas, también se lavo y pinto antes de instalar.

Una vez realizamos la instalación de todo nuevamente aprovechamos de reemplazar todas las mangueras del sistema hidráulico para que el equipo pueda tener un mantenimiento preventivo de hora cero a partir de todo lo ya realizado y poder operar de manera inenterrumpida.

Al poner en marcha el equipo operó correctamente así que lo enviamos a la empresa para su entrega, cuando el equipo estaba ya en operaciones recibimos un llamado de que la falla en la elevación de carga persiste así que fuimos hasta allá a verificar que estaba pasando.

Al llegar notamos que el equipo estaba siendo operado de manera incorrecta en muchas formas, la primera que notamos es que los operadores estaban utilizando el freno de la transmisión como un croche lo que recalentaba la transmisión y a la hora de elevar estaban elevando una carga de 2000kg.

Tocó explicarles que este equipo está diseñado para trabajar con una carga nominal de 2000kg y debido al tiempo que tiene el equipo no debían exceder de los 1500 a 1700kg como capacidad máxima, ahí si el equipo funcionó perfectamente por lo que se está organizando proporcionar una capacitación a los operadores de la empresa para evitar daños innecesarios y la posibilidad de accidentes laborales por malas operaciones.

Estos equipos una vez los usas de manera indebida los riesgos de accidentes aumentan mucho ya que se varía el centro de gravedad de el equipo y se puede voltear o suspender en la parte trasera, sin tomar en cuenta que puede dañar la parte interna de los cilindros hidráulicos lo que puede ocasionar que la carga se desplome.

Todos estás posibles fallas traen muchos riesgos y gastos innecesarios para la empresa.

Espero que les haya gustado está intervención, gracias por leer mis líneas y que Dios les bendiga grandemente.

Las fotos son de mi propiedad tomadas con el celular Infinix Hot 10 i.

https://twitter.com/1388439908650455040/status/1589967082770567168

The rewards earned on this comment will go directly to the people( @soychalbed ) sharing the post on Twitter as long as they are registered with @poshtoken. Sign up at https://hiveposh.com.

Hello, how about reading a bit of your post, I realized that most of the mechanical and automotive problems for cars is the flow of oil between its parts, sometimes I don't know how to place oil How it should be or what it should be or how much It must be and for this reason a fault similar to yours occurs, the oil has not been its normal path and the device did not perform the correct function but was forced. thanks for your post

I recommend you to read the owner's manual of your car, there are certain rules that if you comply with them as they should, the car will operate correctly and extend the life of the car.

Congratulations @soychalbed! You have completed the following achievement on the Hive blockchain and have been rewarded with new badge(s):

Your next target is to reach 29000 upvotes.

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPSupport the HiveBuzz project. Vote for our proposal!