What factors are involved in the casing of an oil well?

There are some conditions that make an oil well to be cased, for example when we lower a casing pipe into the well and then cover the space between the pipe and the walls of the hole we are isolating areas of interest such as aquifers, with this we achieve that the surface aquifers are not contaminated.

Another condition is the geological, that is to say, when we drill a well the first strata are quite unstable, which requires that we revet the well to give support to the walls of the hole in its most unstable zones. However, there are deep wells that are also cased, so in some way you may wonder:

Why at high depths is a well still lined?

Although at high depths there are consolidated lithological formations, the well is cased with the intention of being able to handle the high pressures of the drilling fluid with which the subsequent phase will be drilled, with this we will also achieve a greater facility to complete the well with accessories that help to produce an oil with less percentage of sanding and greater production capacity.

What is a casing pipe?

It is a pipe that meets the necessary requirements to be left inside the well to later add a cement slurry between the space between the walls of the well and the outer walls of the pipe.

From experience I can tell you that when I supervised drilling and well construction operations in the area of Tomoporo (South of Lake Maracaibo, Trujillo State - Venezuela) the casing pipes were lowered with centralizers, all with the intention that these pipes will be embedded in the well in a centralized manner and thus that the cementing could be performed and will be evenly proportioned inside the hole.

There is a feature that makes distinctive this type of pipe with drill pipes, the difference is that casing pipes are larger in diameter than drill pipe. I can also mention that engineering has been very creative and has provided many solutions in the operations of lowering casing pipes to the well, an example of this is that to optimize the economy in the construction of the well, it has been implemented not to cement the last section of casing that is lowered into the well, which is why a hanger system has been invented to lower a hung liner that facilitates that the last section of the well is not cemented.

How does petroleum engineering contribute to casing lowering operations?

Petroleum engineering studies and analyzes the different forms of designs that can be implemented in the operations for running casing down the well, with the design what we want to achieve is the decrease of the construction costs of an oil well, the reasons are very simple and I explain them below:

One of the functions of casing the well is to support the high pressures at the bottom of the well, which is why the pipes to be lowered into the well are not built with the same material, the deeper they must withstand more pressure, the pipes that have to withstand more pressure are more expensive, Therefore, a design must be made where it is specified from which initial and final length interval must be lowered a certain kind of pipe that can withstand certain pressure, this without overdesigning, ie if a section I support a certain pressure, you should not buy a type of pipe that is above that pressure because it comes out more expensive, nor can you buy a pipe that does not support the minimum pressure because it would be crushed by the pressure of collapse.

The design must also include the torques that the pipe can withstand according to the geological conditions of the subsoil, also are objectives of the design what it can withstand by temperature, the order of the diameter is important because when a casing pipe is lowered, the diameter must be of such size that it can pass the drill pipe with a bit diameter with a smaller diameter to fit inside the casing pipe to drill the next section of the well.

Conclusion

It is more than clear that when we casing the well we are protecting it from many adverse factors, however you have asked yourself: How would a mechanical configuration of the well look like expressed in a diagram?

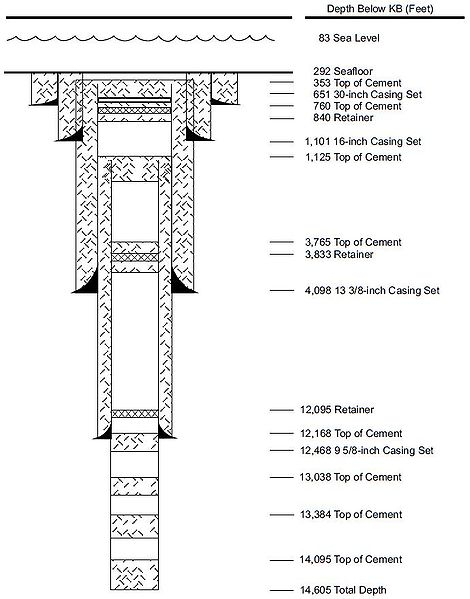

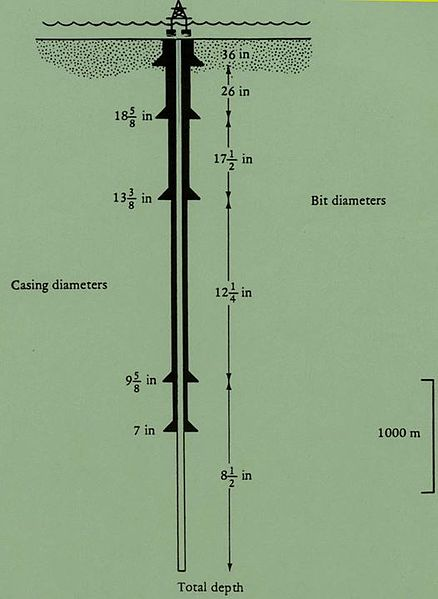

Each well has the necessary conditions so that there is a distinctive mechanical configuration for each one, however in a generalized and very common way some deep oil wells could have a diagram whose mechanical configuration is the following:

In the diagram it can be perfectly observed how on the right side the drill bit diameters are described, while on the left side the external diameters of the casing pipe are shown, logically the diameters of the drill bit are smaller than those of the drill pipe, since in this way the drill pipe string fits inside the casing pipe and in this way the drilling of the subsequent hole can be carried out.

References consulted and recommended for further reading

Identifying Casing While Drilling (CwD) Potential in Geothermal Scenario Along with Economics

Analysis and optimization of control algorithms for RSSTSP

for horizontal well drilling

!1UP

You have received a 1UP from @luizeba!

@ccc-curator, @stem-curator, @neoxag-curator, @pal-curatorAnd they will bring !PIZZA 🍕

Learn more about our delegation service to earn daily rewards. Join the family on Discord.

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider delegating to the @stemsocial account (85% of the curation rewards are returned).

You may also include @stemsocial as a beneficiary of the rewards of this post to get a stronger support.